Flexible packaging is one of the most widely used and preferred types of packaging, especially for industrial and commercial purposes. According to Statista, the market value of flexible packaging material is estimated to touch US $56.3 by 2025. Flexible packaging offers many benefits, such as cost-cutting, space-saving, and resource efficiency, that make it suitable for packing food products, drugs, cosmetics, and electronic gadgets.

The recorded history of flexible packaging dates back to the 1st or 2nd century BCE, when trading across Europe and the Asian

continent was prevalent. Processed thin barks and leaves were used as the most common flexible packaging material. Textile products like cloth, jute, and gunny bags were also used for packaging. However, the introduction of paper in China brought about a significant shift in packaging materials. Nevertheless, a major transformation occurred with the advent of plastic in the 19th century, owing to its cost-effective mass production and appealing characteristics, such as exceptional barrier capability, airtight sealing, and the ability to be customized according to specific needs.

What is flexible packing?

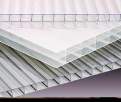

It refers to the packaging of products using non-rigid materials that adapt according to the product's shape to be packed. This property makes them a highly customizable packaging option. Each type of flexible packing material possesses one or more properties like malleability, ductility, tensility, stretchability, retractability, twist-retention, puncture-resistance, barrier efficiency, airtight nature, and most importantly customizability.

Two key components come under the purview of flexible packaging:

1. The type of material or substrate (an underlying layer) used

2. The design of the packaging material

The most commonly used materials for flexible packaging are plastic and polymers such as BOPA, BOPP, BOPET, CPA, CPP, aluminum foils, and paper. They are available in multiple designs like shrink films, cling films, stretch films, sheets, labels, stand-up pouch bags, and more such customizable designs.

Advantages of using flexible films for packaging

There are several benefits of using flexible packaging options that range from safety and practical resource utilization to adding commercial value, such as convenience and attractiveness.

1. Safer distribution

Businesses that involve product distribution need to be cautious while choosing the packaging material, which is the main factor that will ensure safe and damage-free delivery. Especially in the case of food products, flexible substrates offer several benefits, such as increased shelf life, unaltered quality, taste, and texture. Further, airtight packaging, such as sachets, will eliminate the possibility of pilferage and contamination.

2. Lighter weight

The product's weight and the packing material used are crucial for any product to be transported. It will decide the cost, mode of transportation, workforce, and resources required for the shipping. Flexible packaging materials such as foam and bubble wrap potentially reduce the product's overall weight compared to conventional non-flexible packaging material. Above all, it can potentially reduce the risk of damage; for example, tablets are packed using airtight blister packs made of thin metal films.

3. Cost-effectiveness

In general, flexible packaging materials are cost-effective in terms of manufacturing as well as purchasing the packing material for commercial use. The reduced cost is because flexible packaging materials generally consist of thin layers of multiple substrates, which require fewer quantities of raw materials. In addition, multilayered packing material makes the package tamper-resistant, thereby avoiding product rejections.

It can reduce product packaging and shipping costs, becoming more cost-effective than regular packaging. For example, Amazon launched 'frustration-free' packaging that aims at avoiding shipping boxes for the products for which boxes are not mandatory, and this significantly reduced the shipping costs due to lesser weight.

4. Convenience that adds commercial value

Flexible packing materials can be easily customized with add-ons such as zip locks, spouts, nozzles, resealable seals, etc., which makes the product more convenient to use and preserve.

5. Sustainability

Though the raw materials used to manufacture flexible packaging materials seem to be plastic and polymers, this is only sometimes the case. There are even organic degradable substrates that are used as raw materials. Moreover, plastic and inorganic components can be systematically recycled and reused, which makes it promising to ensure sustainability. Also, the lesser quantity of raw materials minimizes resource utilization, becoming a sustainable packaging option.

Product-wise benefits associated with flexible packaging

Flexible packaging films such as BOPET(biaxially-oriented polyethylene terephthalate), BOPA(biaxially-oriented nylon), BOPP(biaxially-oriented Polypropylene), CPA(cast nylon), CPP(Cast Propylene), and aluminum foils are most widely used in industries for packing edible products such as food, pharma products, cosmetics, and electronic equipment. The same material with varying thicknesses and designs will be used in each of these industries according to the product's characteristics and consumer needs. Now, let's look into each one separately.

Food products

There is a wide range of food products being packed and transported daily. Each type of food product demands a particular way of packaging to ensure the promised shelf life, texture, taste, and nutritional value. For instance, dry food products such as rice are packed using LDPE films, whereas dry powders such as pet food use laminated BOPP bags with valves.

Medical and pharmaceutical products

Packing pharmaceuticals such as tablets, capsules, tonics, spirits, and first aid materials requires utmost safety to avoid contamination and moisture exposure while ensuring increased shelf life. Flexible packaging offers high reliability as they are predominantly lightweight. Also, they consume fewer resources and energy to manufacture, minimize shipping charges, and offer manageable waste disposal, which is very important for the medical industry. The most commonly used packaging designs include blister packs, IV bags, and barrier pouches.

Cosmetics

It is undeniable that packaging can effectively add aesthetic beauty while resonating with the brand voice. Flexible packaging offers numerous benefits for cosmetic items as it enables airtight sealing and higher filling volumes that make it easy to squeeze and utilize the product to the fullest without waste. Beauty products such as oils, lotions, powder, cream, and gels need spill and puncture-proof packaging, so the most commonly used containers are sachets, barrier pouches, and zipper pouches. They are travel-friendly and child-friendly for childcare products.

Electronic equipment and insulation materials

Packaging is of prime importance and a key selling point for electrical and electronic gadgets. Such gadgets might dissipate heat, current waves, electromagnetic waves, chemicals, and radiation from batteries and circuits. Such emissions should be blocked and insulated to prevent damage to the external environment while protecting the equipment from external forces such as physical damage, moisture, and climate. Foam and thermoformed plastic films are the most commonly used materials for packing electronic equipment and instruments.

Latest trends in flexible packaging

According to stats published by Statista in 2019, plastic wastage from the e-commerce domain alone crossed over one billion tons, which is alarming. Moreover, with increasing awareness of sustainability from both the consumer's and the vendors' side, the e-commerce sector prefers 100% biodegradable and recyclable packaging material, according to a survey conducted by Mordor Intelligence in 2022. As a step towards reducing plastic waste, there is the increased usage of paper-based packing materials. Stats published by Statista indicate the increase in the market value of the global plastic packaging segment in kilotons till 2020 and the expected growth by the end of 2023.

Summary

Flexible packing materials are becoming an indispensable method of packaging food items, medicines, cosmetics, electronic gadgets, etc., among industries, commercials, and retailers. Considering the wide range of benefits, it is becoming popular even among non-commercial and personal uses such as shifting or sending products.

Despite challenges like the rising cost of raw materials, rapid technological advancements, sustainability, and choosing the most suitable substrate for a particular product, there are top-notch packaging solution providers who can readily suggest and offer a cost-effective solution.

If you want to learn more about flexible packaging or looking for packaging solutions, please emailinfo@webpackagingsolutions.com or call +1-832-953-3192/96.